Cnc Usb Controller Mk2 Software Remains User

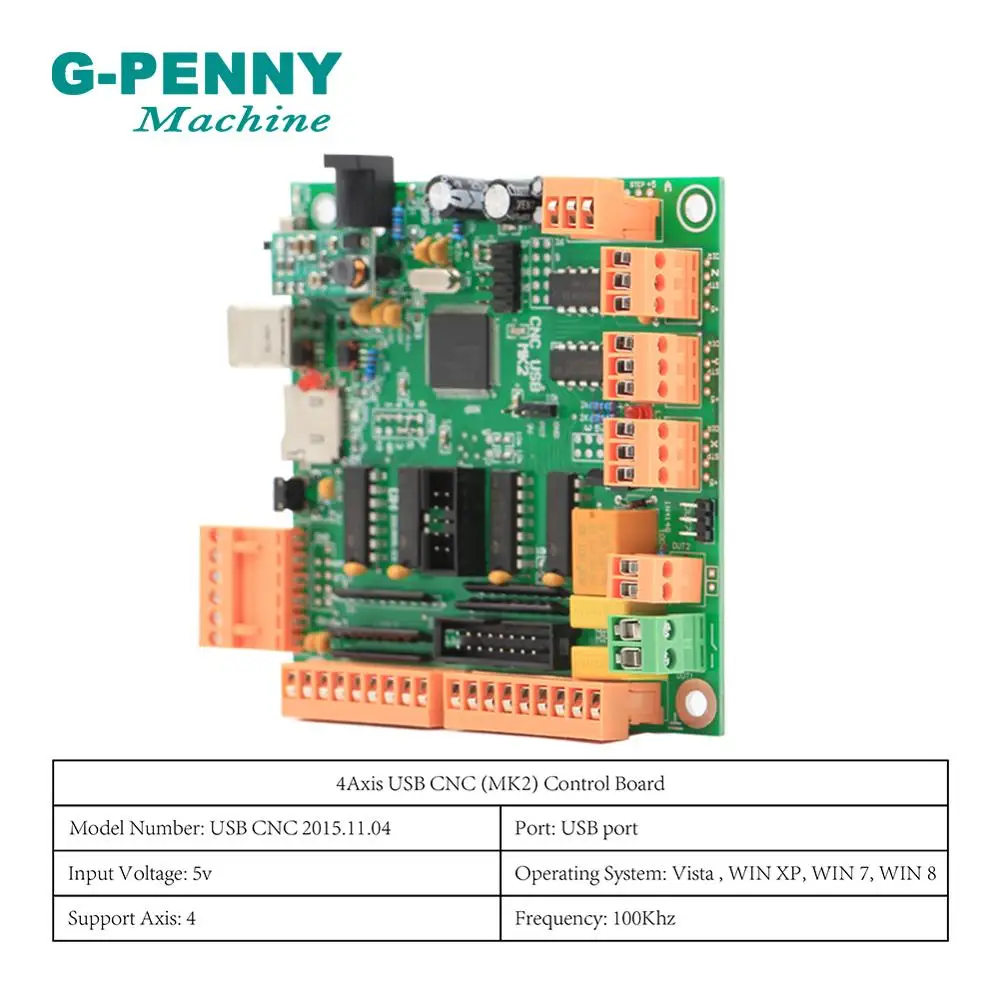

Configuration options allow for maximum flexibility, integration and customization.CNC Controller: Software, Drivers, & Boards Mch m cnc usb controller s dng phn mm ca Planet CNC giao tip USB tin li.S trc iu khin : 4 axis, 9 axisC 2 phin bn l MK1 v MK2. Even those new to CNC machining can employ advanced functions with little difficulty. At the same time the software remains user friendly. Website: Online Shops: Skpe:+8618910813208 2 Software 2.1 Overview CNC USB Controller software is designed to fully exploit the advanced features of controller hardware.

Cnc Usb Controller Mk2 Code Or The

Manuals and sample g-code: - Software user manual - Mk3 user manual - Mk3/4 user manual - Mk2 user.The CNC Controller or CNC Control is the package of electronics and software that take input either from g-code or the cnc control panel and converts it to the signals the CNC machine’s motors need to move the CNC axes.CNC USB CONTROLLERS. CNC USB Controller User manual. Set settings like this: If you use 2 relays and 0-10V connect output board terminals to controller like this: S OUTPUT7527F Installation and Set-up. If you use 3 relays connect output board terminals to controller like this: S not connected 0 GND 1 OUTPUT1 2 OUTPUT2 3 OUTPUT7. For Mk2/4 controller: Connect Mk2/4 controller with wires to screw terminals.

CNC USB Controller Mk2 - Planet CNC. Before any work is done with machine you must be sure that the. This tutorial is intended to help you with production of single side PCBs with your CNC machine, Gerber files and PlanetCNC TNG software.

You might find the article I did that analyzes what features Hobby CNC Controllers are missing compared to industrial controls intersesting. If they keep coming down, these controls may make more sense on a DIY CNC Project than it seems.I’m not going to talk further about these controls as they’re a pretty advanced topic. It looks like they’re testing the low-end market. Industrial Quality Servo Drives, Home / Limit Switches, and all the rest really run up a hefty price tag in a hurry.While these controls are expensive, lately I’ve seen controls such as the low-end of the Siemens line coming down in price in places like eBay. Not only is the controller itself expensive and fairly hard to come by (though one does see them from time to time on eBay), but Industrial OEM Controllers expect premium sub-components too. They’re the very hind end of the market.These are not very common for DIY projects due to their expense.

LinuxCNC (My personal favorite!)LinuxCNC has its origins in NIST’s “Enhanced Machine Controller” project, hence its original name “EMC” and “EMC 2”. The next closest was LinuxCNC. Art wanted a CNC Controller that runs on Microsoft Windows PC’s rather than Linux, so it took a major rewrite and the two don’t share much in common any more.According to our 2017 Survey, Mach 3 is the most popular CNC Controller at the low-end, with 47% market share. Mach 3Art Fenerty founded ArtSoft in 2001 and launched Mach 3, which was based on an offshoot of the original EMC (which is now LinuxCNC) code base. PC Based CNC ControllersThere are three main players in this market:All three have good reputations with varying trade-offs of features, functionality, price, and ease of use. They’re also sold as a way to update obsolete controls on industrial CNC Machines to bring the more up-to-date features and performance.They’re still not cheap, but they’re starting to fall into the range of what a DIY CNC’er might afford.

I put pencil to paper one time comparing it to a Mach3 system and I found that if you configure a system with all the capabilities of FlashCut (like a USB pulser for Mach3) that the premium isn’t as high as you may think.Having a completely engineered turnkey system that’s plug-and-play is worth a bit of premium if you ask me. Here’s a great video by Dave DeCaussin (one of the original founders of FADAL) showing how easy it is to set up a FlashCut system:I’ve heard some folks say they think the FlashCut is too expensive compared to other solutions. The company was started back in 1993, so it’s been around a long time and the design is very mature.While its Market Share isn’t as big as Mach3 or LinuxCNC, I’ve heard nothing but good about FlashCut.

Microcontrollers: USB, Arduino, Rasperry Pi, TinyG, & MoreMicrocontrollers allow CNC Controllers to be built that are cheap and fit into a small space.CNC Microcontrollers are a relatively new development made possible by continued advances in miniaturization and software. From my perspective, the jury is still out–not enough market share or experience to bet on it when the competition is well entrenched and has far larger installed bases. The developers claim it shares less than 1% of Mach 3’s code.It’s quite a bit more expensive, but in theory, should be better. It’s almost a start over from scratch rewrite of Mach 3.

TinyG / TinyG2TinyG is another microcontroller-based system. The Shapeoko people told me they evaluated a bunch of these and felt GRBL was head and shoulders the winner for their needs. It’s open source, and in use by a lot of different firms including:That’s pretty much an all-star cast, so you can be sure GRBL has a vibrant ecosystem of products and people who can help and also that it has a bright future.

By default, TinyG controllers have 4 stepper motor drivers while gShield (used with grbl) has 3. While grbl is 3-axis (XYZ), TinyG is 6-axis so can support additional rotary axes. TinyG claims to do some things better or differently: The TinyG codebase was forked from grbl in 2010 and has been going its own way ever since.

Breakout BoardThe role of the Breakout Board is to take a connection from your PC and generate the appropriate signals needed to operate the Motor Drives, VFD, and Contactors.For a deeper dive on Breakout Boards, see our article: The most common breakout boards, such as the one pictured above, are connected to your PC’s parallel port. CNC Controller ElectronicsHere’s the sort of electronics you’ll find inside most CNC Controller cabinets:Let’s go over the function of each. In our 2017 CNC Controller Survey, GRBL had #1 market share, PlanetCNC #2, and TinyG #3 among the microcontrollers. Like TinyG, it’s also a 4-axis solution. TinyG claims its implemented on a higher performance microcontroller that has more memory.PlanetCNC is a single-board CNC Controller that hails from Slovenia, Europe.

Switching polarity reverses direction to counter-clockwise. Direction: If the polarity of direction is one way, it commands the motion to be clockwise. Step: Each pulse on the step line tells the motor drive to move the motor 1 step. The result is much higher performance a at a slightly higher cost.We also have a great article on Motion Control Boards: Motor Drives / DriversGiven a breakout or motion control board, your PC’s signals are converted to 2 signals: These boards can connect via USB or Ethernet cable.It’s impossible to control a USB connection finely enough to directly generate the precise pulses needed by Axis Motor Drives, so the role of a Motion Controller is to accept higher level commands and generate the pulses. In addition, there are a lot of performance and reliability issues associated with breakout boards.Newer and more sophisticated models are actually motion control boards, though some may still refer to them as breakout boards.

Your breakout board typically supplies a 5V DC signal. In this case, most contactors are used to switch AC, for example to control a coolant pump. You may need to purchase or build a DC power supply to provide power to your motor drives.One of the first CNC Controllers I built used this DC Power Supply:Contactoris a fancy name for a relay capable of being used for higher voltages. That’s very convenient, but not always the case. DC Power Supply (Not Shown)The photo above did not show a DC power supply because the motor drives used are capable of accepting AC. In exchange, it pumps out power to the motor in such a way as to control its motion.

0 kommentar(er)

0 kommentar(er)